Rotary Gear Pump

Product Details:

- Color Blue

- Theory Centrifugal Pump

- Structure Diaphragm Pump

- Power Electric Watt (w)

- Pressure Low Pressure Bar

- Usage Water Oil Well Water Well Food Boat Paper Printer Cosmetics Air Pump

- Application Cryogenic Fire Submersible

- Click to View more

Rotary Gear Pump Price And Quantity

- 5000 INR/Unit

- 1 Unit

Rotary Gear Pump Product Specifications

- Cryogenic Fire Submersible

- Blue

- Water Oil Well Water Well Food Boat Paper Printer Cosmetics Air Pump

- Electric Watt (w)

- Low Pressure Bar

- Centrifugal Pump

- Diaphragm Pump

Rotary Gear Pump Trade Information

- 50 Unit Per Month

- 1 Week

- Africa Asia Middle East

- All India

Product Description

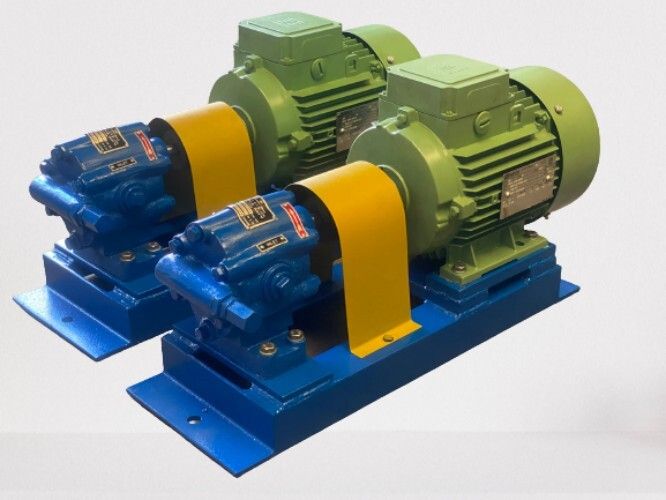

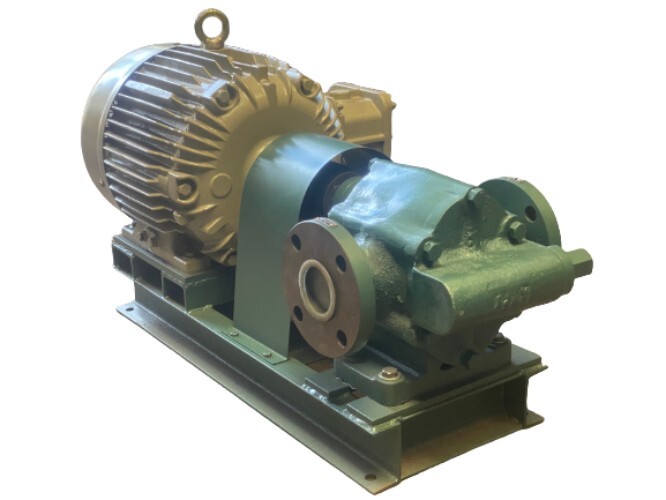

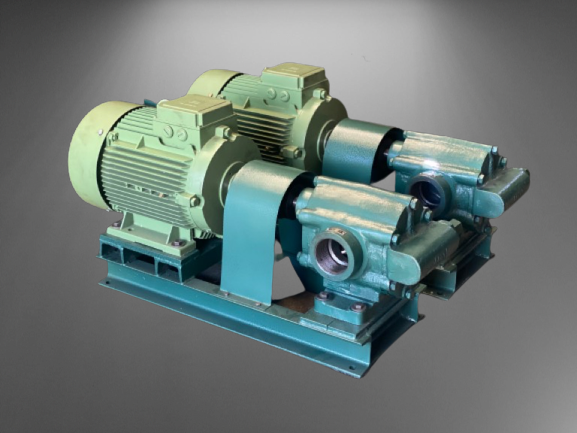

Rotary Gear Pump

Established in the year 1980, ours is a trusted name in this domain engaged in manufacturing, exporting and supplying a superior grade of Rotary Gear Pump. These gear pumps are designed such a way that it utilizes the meshing of gears to pump fluid by displacement. It is used in transferring various grades of oils and chemicals such as diesel, fuel, odium silicate, caustic soda, castor oils and various others. Rotary Gear Pump offered by us has following distinguished features:

- It Is Easy To Operational

- Our Offering Rotary Gear Pump Great Smooth Running

- Eye Catching & Sturdy Design

- Long Lasting With Longer Service Life

- These Are Resistant To Varied Conditions

- Ensures With Splendid Performance

- Our Rotary Gear Pump Is Reliable & Efficient

- Available In Medium Duty, Heavy Duty And Extreme Duty Models - In Cast Iron, Cast Steel And Stainless Steel

- It is Highly Efficient and Low Cost Positive Displacement Pumps

- Our Standard Model Pump Of This Series Can Entertain Fluids Upto 80 Deg.

Specification

|

Brand |

Ajay Engineering |

|

Power Source |

AC Powered |

|

Motor Horsepower |

3 HP |

|

Head |

0-5m |

|

Phase |

Single |

|

Design Type |

Standard |

|

Model Name/Number |

Pump |

|

Maximum Pressure |

50-100 bar, 100-150 bar, 150-200 bar |

Frequently Asked Questions:

1.Where is a rotary equipment pump used?

Ans. Rotary Gear Pumps are commonly used for pumping excessive viscosity fluids such as oil, paints, resins, or foodstuffs. They're also favored in programs wherein correct dosing or high-strain output is needed.

2.How does a rotary pump work?

Ans. Rotary vane pumps include two or extra chambers that compress, rotate, and discharge gasses and drinks. Those chambers create a vacuum that pressurizes the contents, permitting them to tour via the pump's outlet. The vanes slide in and out and flip towards the internal wall of the rotor.

3. What are the blessings of a rotary pump?

Ans. High performance with low life cycle fees on the identical time. As compared to different high-quality displacement pumps, the rotary lobe pump has very excessive performance. This results in considerably lower strength consumption. A widespread benefit, as energy costs are a large part of the lifestyles cycle expenses.